Forward Electronics Co., Ltd. Environmental Policy

In order to contribute to the construction of a healthy and comfortable living environment and to pursue the sustainable growth and development of human beings, we actively fulfill our corporate environmental responsibility and mission. In addition to devoting ourselves to the technical improvement of electronic components in China, we are committed to developing green products to meet customer requirements In the future, the prosperity of the enterprise and the environment will coexist.

The company's labor-management relations are harmonious and harmonious. It organizes employee tourism activities and hiking activities, and praises excellent model workers every year.

We are willing to dedicate ourselves to:

1. Meet government environmental regulations and customer environmental requirements, and respond to global environmental movements.

2. Introduce energy-saving and low-pollution materials and equipment.

3. Actively carry out industrial waste reduction and resource recovery.

4. Improve environmental performance and prevent pollution.

5. Communicate environmental protection messages to colleagues, customers, suppliers and other stakeholders.

Forward Electronics Co., Ltd. will continue to educate all my colleagues to comply with the requirements of the environmental management system in order to fulfill our commitment to environmental protection and make the company stand forever in the mountains and rivers.

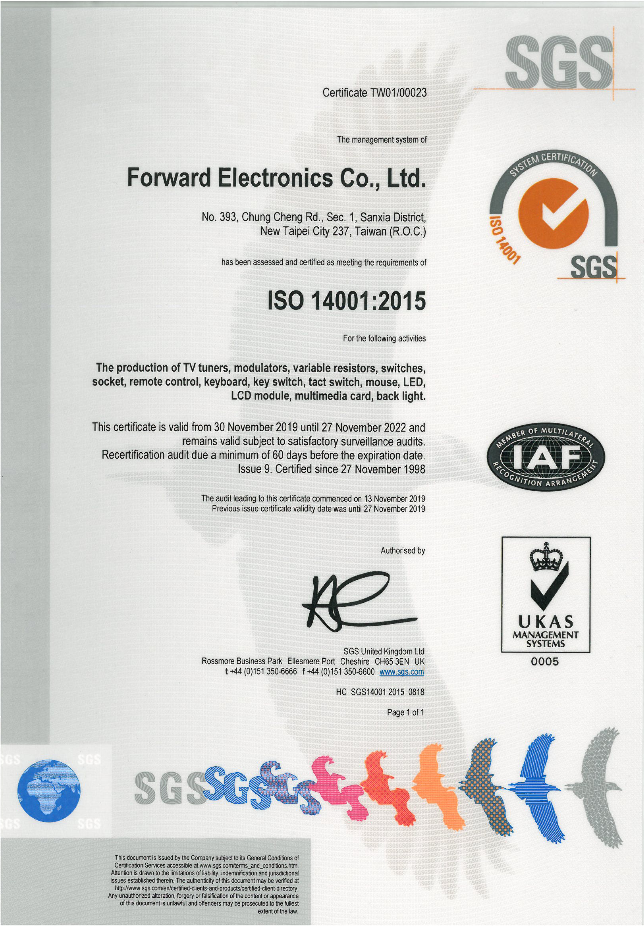

ISO 14001 certificate

| Period: | Implementation content: |

|---|---|

| From 2015 to 2017 | Electricity Saving The goal is to reduce electricity consumption by 2% in the year of electricity saving. The electricity consumption in 105 years is 5,834,800 kWh, which is 6,124,200 kWh, which is a reduction of 289,400 kWh. Through the frequency conversion improvement of the cold-adjusted cooling water system, the power consumption is reduced, and the entire plant area is replaced with LED lamps. The air conditioner does not turn on at room temperature below 28 ° C, and the goal of energy conservation and carbon reduction is achieved. |

| From 2015 to 2017 | Water Saving The goal is to reduce water consumption by 1% in the annual water saving. In 105 years, water consumption was 53,020 tons, compared with 54,024 tons in 104 years last year, and water consumption was reduced by 1,004 tons. Through the replacement of old water pipes to avoid wastage of water caused by water leakage, comprehensively install water-saving faucets and strengthen publicity to reduce waste. |

| From 2015 to 2017 | Reduce Carbon Emissions The goal is to reduce carbon emissions by 1% in the annual carbon reduction. In 105 years, the equivalent carbon dioxide emission reduction through the electronic transfer system, the reuse of waste paper, and the energy saving plan is 3 metric tons. |

| 2017.04.21 | Completed noise detection of fixed pollution sources (stamping, automata, ultrasonic compression) in 2017Q1Q2. |

| 2017.05.25 | Completion of domestic sewage discharge water quality inspection for fixed pollution sources in 2017Q1Q2. |

| 2017.08.15 | Completion of 2017 annual stationary pollution source (tin furnace, injection molding machine) air pollutant emission detection. |

| 2017.09.01 | Completed ISO 14001 management review (improved process reduction and waste reduction, saving about NTD500,000 annually). |

| 2017.10.20 | Completed the external audit of ISO14001 environmental system in 2017. |

| 2017.10.23,24 | Complete the external annual audit of the third party RSC commissioned by the client. |

| 2017.10.31 | Completion of Q1 ~ Q3 air pollution, soil pollution and other fees declaration. |

| 2018.06.29 | ISO14001: 2017 environmental management plan, saving a total of NTD424,880. |

| 2018.07.17 | Passed the SGS ISO-14001: 2015 evaluation and obtained a certificate. |

| 2018.08.01 | Solar renewable energy was resold from 2017.11.19 to 2018.08.01 for a total of 27,077 degrees of Taipower, with a subsidy rate of NTD6,5056 per unit of electricity. |

| In 2019 | In order to implement corporate environmental protection responsibilities, the energy saving plan saved electricity consumption of 430K kWh, carbon reduction of 200 metric tons, and a 50KW solar power generation system with an annual power generation of 28,028 kWh. |

| 2019.04 | Sanxia Plant completed the first half of 108 operation environment monitoring report (stamping, automaton, ultrasonic crimping) noise detection. |

| 2019.07 | Sanxia Plant completed the perimeter noise detection. |

| 2019.07 | Sanxia Plant passed the external annual audit of ISO 9001 quality management system. |

| 2019.10 | Sanxia Plant completed the second half of 108 operation environment monitoring report (stamping, automaton, ultrasonic crimping) noise detection. |

| 2019.11 | Kaohsiung Plant passed the external annual audit of ISO 9001 quality management system. |

| 2019.11 | Sanxia Plant passed the annual audit of ISO 14001: 2015. |

Sustainable Operation of Energy Saving and Carbon Environment

Reuse of packaging materials reduces waste of resources; product design uses environmentally friendly materials, material optimization, minimization; Use production technology to reduce waste of materials, and regularly delegate resource waste to the processing industry to ensure that resources are not wasted.